- This topic is empty.

-

AuthorPosts

-

2026-02-11 at 6:00 pm #7675

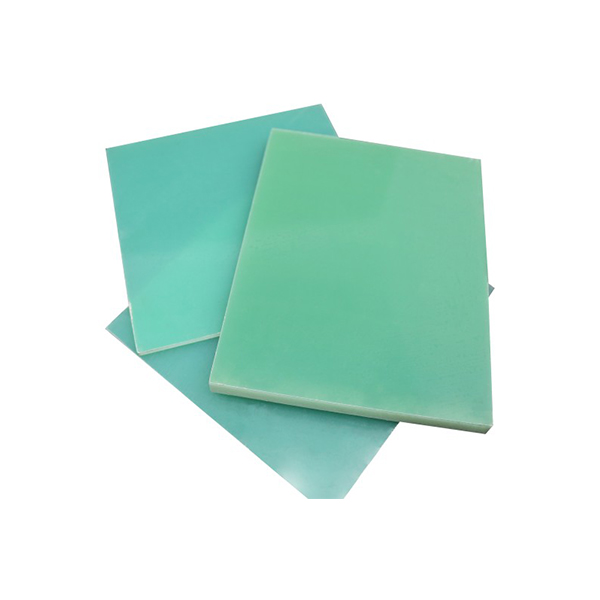

Electrical insulation plays a critical role in the safety, stability, and long-term performance of modern electrical and electronic systems. From power distribution panels to circuit boards and industrial equipment, insulating materials must withstand voltage stress, heat, and environmental exposure without degradation. Among the most widely used insulation materials today is the Green FR4 fiberglass sheet, known for its balanced mechanical strength and electrical performance.

PT. UNIKATAMA INDO PERKASA supplies high-quality Green FR4 fiberglass sheet solutions designed for demanding industrial and electrical applications.

What Is Green FR4 Fiberglass Sheet?

FR4 is a glass-reinforced epoxy laminate material made from woven fiberglass cloth bonded with flame-retardant epoxy resin. The “Green” designation typically refers to its standard epoxy color and stable formulation used in electrical and electronic insulation applications.

Green FR4 fiberglass sheets are engineered to provide:

High dielectric strength

Excellent flame retardancy

Stable mechanical properties

Good thermal resistance

Low moisture absorption

These characteristics make FR4 one of the most commonly specified insulation materials worldwide, especially where reliability and safety are essential.

Electrical Insulation Performance Explained

Electrical insulation materials must prevent unintended current flow, reduce the risk of short circuits, and protect both equipment and operators. Green FR4 fiberglass sheets achieve this through several key performance attributes.

High Dielectric Strength

Dielectric strength refers to a material’s ability to withstand electric stress without breaking down. Green FR4 fiberglass sheets offer consistent dielectric performance across a wide voltage range, making them suitable for:

Switchgear insulation plates

Electrical panel barriers

Transformer components

Circuit board substrates

This high dielectric strength ensures electrical separation between conductive parts, even in compact or high-density designs.

Stable Insulation Under Thermal Load

Heat is a common challenge in electrical systems. Poor insulation materials can soften, deform, or lose insulating properties at elevated temperatures. Green FR4 fiberglass sheets maintain electrical insulation performance under continuous thermal stress.

This thermal stability supports applications such as:

Power electronics enclosures

Motor insulation components

Control cabinets with heat-generating equipment

By maintaining insulation integrity at higher temperatures, FR4 helps prevent failures caused by thermal aging.

Flame Retardancy and Safety Benefits

One defining feature of FR4 material is its flame-retardant behavior. In electrical systems, fire safety is just as important as insulation strength.

Green FR4 fiberglass sheets are designed to:

Resist ignition

Slow flame spread

Reduce fire-related damage in electrical faults

This makes them a preferred choice for electrical panels, distribution boards, and industrial enclosures where safety compliance is required.

Mechanical Strength Supporting Insulation Reliability

Electrical insulation materials must also provide mechanical stability. Cracking, bending, or deformation can compromise insulation effectiveness over time.

Green FR4 fiberglass sheets offer:

High flexural strength

Good impact resistance

Dimensional stability under load

These properties allow the material to act as both a structural and insulating component. For example, FR4 sheets are commonly used as support plates in electrical cabinets where mechanical load and insulation are required simultaneously.

Moisture Resistance and Environmental Stability

Moisture is a major threat to electrical insulation. Water absorption can reduce dielectric strength and lead to leakage currents or corrosion.

Green FR4 fiberglass sheets have low moisture absorption, helping them retain insulation performance in:

Humid industrial environments

Outdoor electrical enclosures

Coastal or tropical regions

This resistance improves long-term reliability and reduces maintenance needs.

Common Industrial Applications of Green FR4 Fiberglass Sheets

Because of their balanced performance, Green FR4 fiberglass sheets are widely used across multiple industries.

Electrical and Power Industry

Switchgear insulation boards

Busbar supports

Control panel partitions

FR4 ensures safe electrical separation while withstanding heat and mechanical stress.

Electronics Manufacturing

Printed circuit board base material

Insulating spacers and fixtures

Test and assembly tooling

The dimensional stability of FR4 supports precise electronic assembly.

Industrial Equipment and MachineryInsulating covers and guards

Electrical mounting plates

Heat-resistant insulating panels

These applications benefit from both insulation and mechanical durability.

Processing and Fabrication Advantages

Green FR4 fiberglass sheets are also valued for their machinability. They can be:

Cut to precise dimensions

Drilled and milled for mounting holes

Machined into custom insulating components

This flexibility allows manufacturers to design application-specific insulation solutions without compromising material performance.

Best Practices for Using FR4 Fiberglass Sheets

To maximize insulation performance and service life, consider the following practices:

Use appropriate cutting tools to avoid edge damage

Avoid excessive mechanical stress during installation

Ensure proper spacing between conductive components

Store sheets in dry conditions before use

Match thickness selection to voltage and load requirements

Correct handling and installation help preserve both electrical and mechanical properties.

Why Choose PT. UNIKATAMA INDO PERKASA

PT. UNIKATAMA INDO PERKASA supplies Green FR4 fiberglass sheets that meet industrial expectations for insulation reliability, consistency, and durability. With a focus on material quality and application suitability, the company supports clients in electrical, manufacturing, and engineering sectors seeking dependable insulation materials.

By selecting proven materials such as Green FR4 fiberglass sheet, engineers and manufacturers can improve system safety, extend service life, and reduce operational risk.

Conclusion

Green FR4 fiberglass sheets play a vital role in improving electrical insulation across modern industrial and electrical systems. Their high dielectric strength, flame retardancy, thermal stability, and mechanical reliability make them a trusted solution for demanding environments.

From power distribution and electronics to industrial machinery, Green FR4 fiberglass sheets provide a balanced insulation solution that supports safety, performance, and long-term reliability.

http://www.unikatamaindo.com

PT. UNIKATAMA INDO PERKASA -

AuthorPosts

- You must be logged in to reply to this topic.