- This topic is empty.

-

AuthorPosts

-

2026-02-11 at 6:00 pm #7674

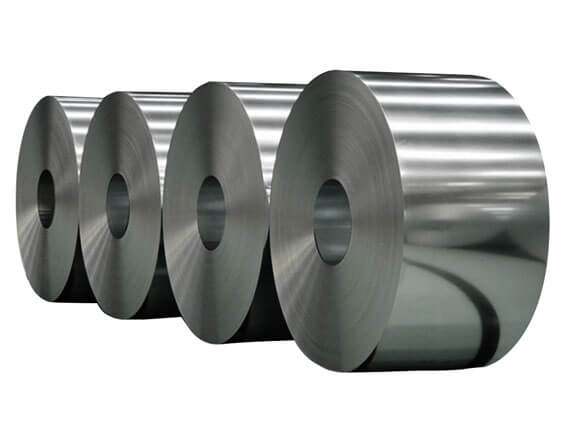

Stainless steel coils are widely used in industries ranging from construction and automotive to aerospace and electronics. These coils, produced from various grades of stainless steel, offer excellent corrosion resistance, high strength, and versatility for numerous applications. Understanding the different grades of stainless steel coil and their specific properties is essential for engineers, designers, and manufacturers to select the right material for their projects.

Understanding Stainless Steel Coils

A stainless steel coil is a flat, rolled sheet of stainless steel wound into a coil. These coils are available in multiple grades, each designed to meet unique requirements for mechanical strength, corrosion resistance, temperature tolerance, and workability. High-quality stainless steel coils from Chuanghe Special Alloy are manufactured to strict industry standards, ensuring reliability and performance in demanding applications.

Common Grades of Stainless Steel Coils

Stainless steel coils are classified into several grades based on composition and mechanical properties. Some of the most common grades include:

1. 200 Series

The 200 series stainless steel coil is an austenitic grade with high manganese and nitrogen content. It is often used as a cost-effective alternative to the 300 series.

Properties:

Moderate corrosion resistance

Good formability and ductility

High strength under certain conditions

Applications: Kitchen equipment, automotive trim, and low-corrosion industrial components.

2. 300 Series

The 300 series is the most commonly used austenitic stainless steel coil, known for its excellent corrosion resistance and versatility.

Properties:

Superior corrosion resistance, especially against acids and alkalis

Excellent weldability and formability

Non-magnetic in the annealed state

Applications: Food processing equipment, chemical industry components, architectural facades, and medical devices.

3. 400 Series

The 400 series includes ferritic and martensitic stainless steel coils, which are magnetic and offer higher hardness.

Properties:

Good wear resistance and moderate corrosion resistance

Excellent strength and toughness

Magnetic properties

Applications: Automotive exhausts, industrial machinery parts, blades, and springs.

4. Duplex Stainless Steel

Duplex stainless steel coils combine austenitic and ferritic structures, offering high strength and corrosion resistance.

Properties:

Superior resistance to stress corrosion cracking

High tensile strength

Excellent durability in harsh environments

Applications: Oil and gas equipment, chemical processing, desalination plants, and marine applications.

5. Specialty Stainless Steel

Certain high-performance stainless steel grades, such as nickel-alloyed or precipitation-hardened steels, are designed for extreme conditions.

Properties:

High corrosion resistance in extreme chemical environments

Excellent mechanical performance at high temperatures

Tailored properties for specific industrial needs

Applications: Aerospace components, high-temperature industrial machinery, and nuclear power systems.

Chuanghe Special Alloy offers specialty stainless steel coils that meet stringent requirements for aerospace, chemical, and high-temperature applications.

Key Factors in Choosing the Right Stainless Steel Coil

Selecting the appropriate stainless steel coil grade depends on several factors:

-

Corrosion Resistance: Evaluate environmental exposure, including moisture, chemicals, or high salinity.

-

Mechanical Strength: Determine load, wear, and impact requirements for the application.

-

Workability: Consider formability, weldability, and ease of machining.

-

Magnetic Properties: Some applications require non-magnetic materials.

-

Cost-Effectiveness: Balance performance requirements with budget constraints.

Consulting with a reliable supplier like Chuanghe Special Alloy ensures the chosen stainless steel coil meets performance and compliance standards.

Applications Across Industries

Stainless steel coils are versatile and integral to many industries:

Construction: Structural elements, roofing, and facades.

Automotive: Exhaust systems, trim components, and chassis parts.

Food and Beverage: Equipment, storage tanks, and processing lines.

Electronics: Enclosures, heat sinks, and chassis.

Chemical Industry: Tanks, pipes, and valves exposed to corrosive materials.

Each application requires careful consideration of the coil grade to optimize performance and longevity.

Advantages of High-Quality Stainless Steel Coils

High-quality stainless steel coils provide several advantages:

Durability: Long-lasting performance in harsh environments.

Corrosion Resistance: Maintains integrity in chemical, saline, or humid conditions.

Versatility: Suitable for a wide range of industrial and commercial applications.

Aesthetic Appeal: Polished finishes and surface treatments enhance visual appeal.

Ease of Fabrication: Can be cut, bent, and welded with precision.

By choosing premium stainless steel coils, manufacturers can ensure reliability, performance, and cost-efficiency.

Conclusion

Understanding the different grades of stainless steel coils and their applications is essential for making informed decisions in manufacturing and engineering. From the versatile 300 series to high-performance specialty alloys, each grade offers unique properties to meet specific industrial needs. High-quality stainless steel coils from Chuanghe Special Alloy provide durability, corrosion resistance, and versatility, making them a trusted choice for industries ranging from construction and automotive to chemical processing and aerospace.

http://www.chuanghealloy.com

Chuanghe -

-

AuthorPosts

- You must be logged in to reply to this topic.