- This topic is empty.

-

AuthorPosts

-

2025-12-02 at 6:02 pm #6795

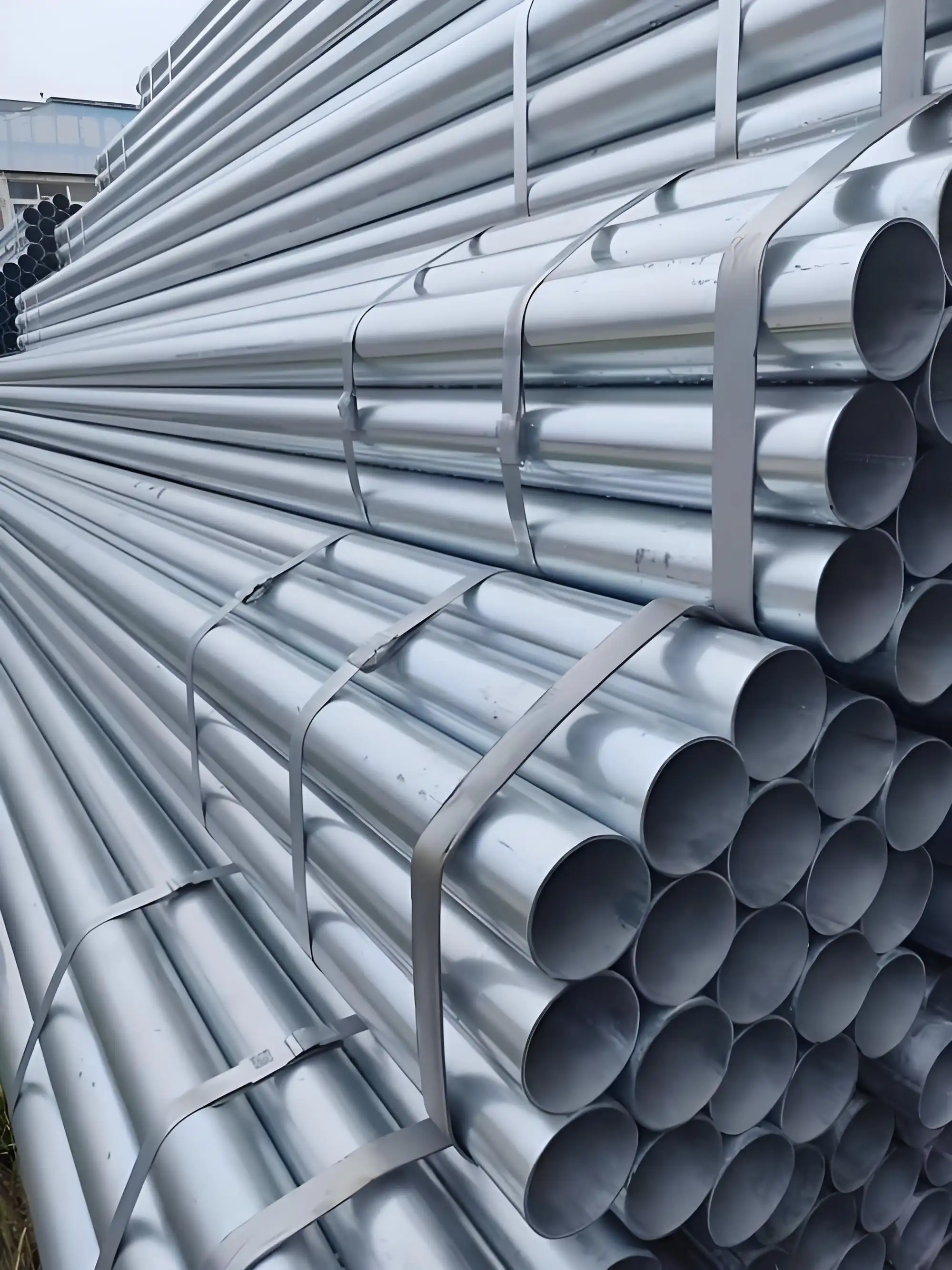

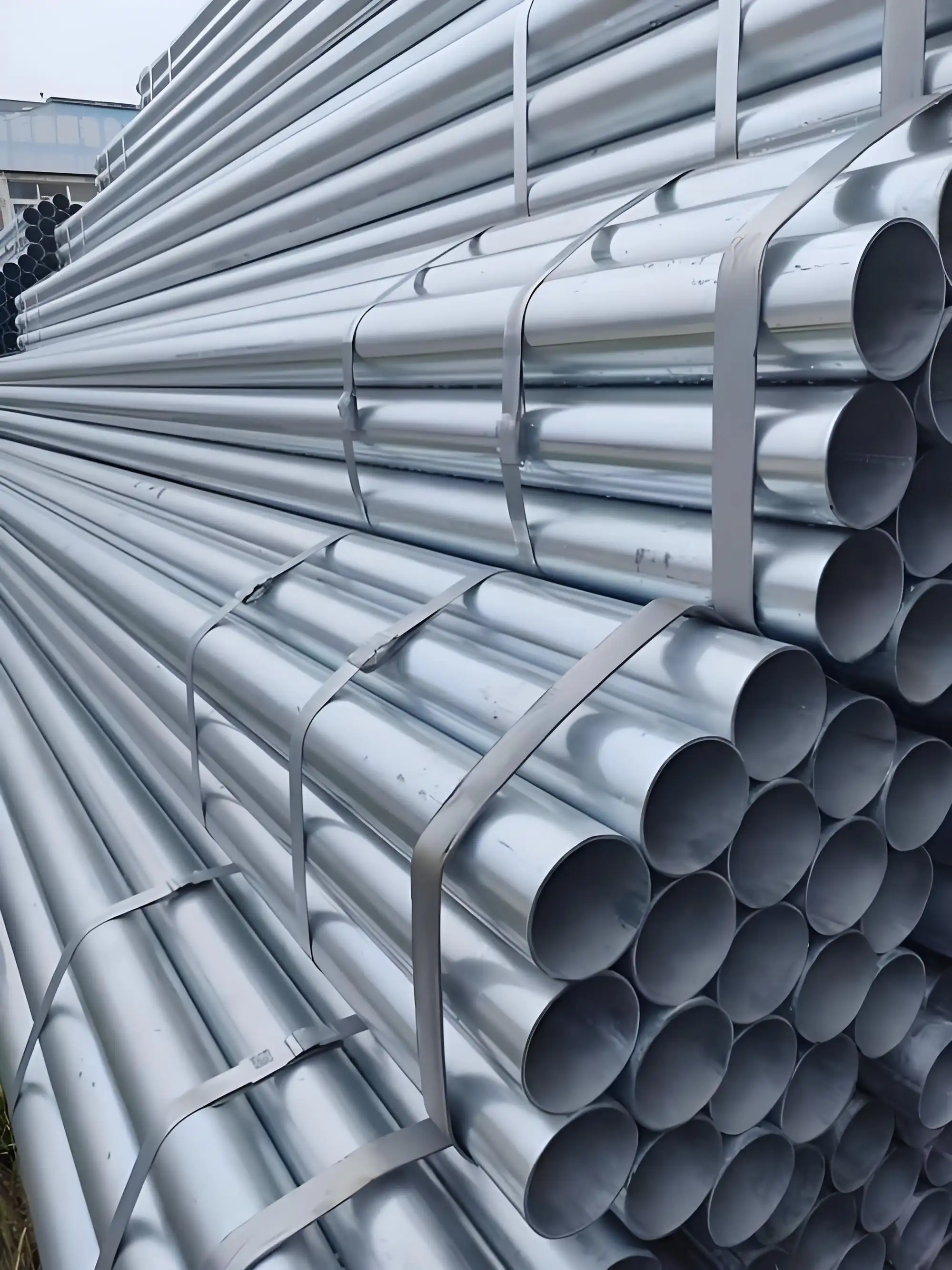

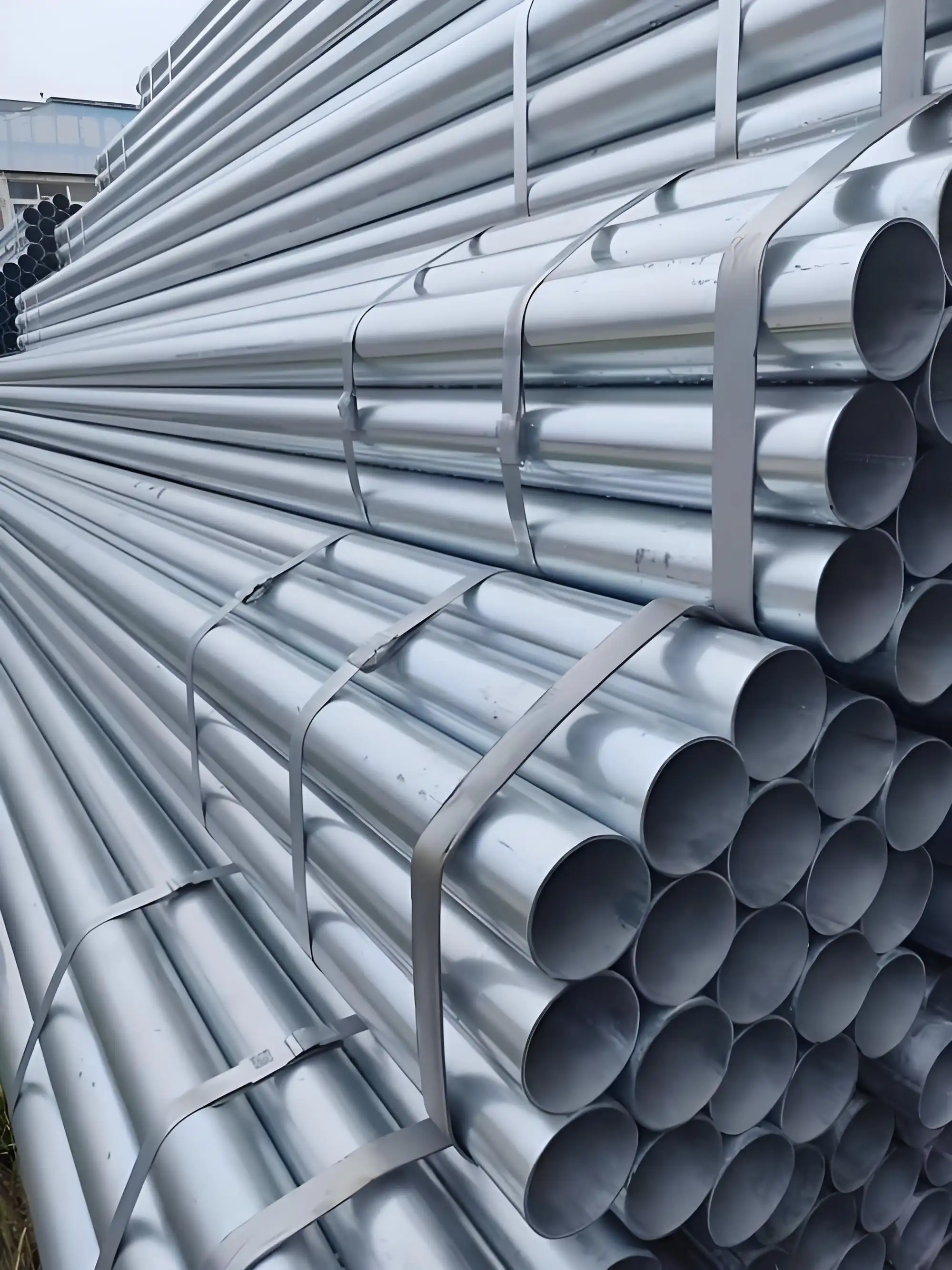

Choosing the right type of galvanized steel pipe is essential for ensuring the success, safety, and longevity of any engineering or construction project. With a wide variety of pipe materials and specifications available, engineers and project managers must carefully evaluate multiple factors such as environment, load-bearing requirements, and cost-efficiency before making a decision. As a trusted manufacturer and supplier of galvanized steel pipes, Guangqi offers a complete range of piping solutions—including galvanized steel pipes, galvanized steel-plastic composite pipes, coated pipes, galvanized square and rectangular tubes, and ductile iron pipes—designed to meet the diverse needs of modern infrastructure and industrial applications.

Understanding the Role of Galvanized Steel Pipes

Galvanized steel pipes are coated with a protective layer of zinc that shields the steel from corrosion and oxidation. This process significantly extends the pipe’s service life, making it ideal for both indoor and outdoor applications. They are used across industries for water supply, structural frameworks, transportation systems, and industrial facilities.

Guangqi’s advanced galvanization techniques ensure uniform coating thickness, superior adhesion, and long-lasting corrosion resistance. Whether used in residential plumbing or large-scale infrastructure, these pipes deliver strength, reliability, and cost-effectiveness.

Evaluating Environmental Conditions

One of the most critical steps in selecting the right pipe is evaluating the operating environment. For instance, in coastal areas with high humidity and salinity, corrosion resistance is a top priority. In industrial zones where pipes may be exposed to chemicals or high temperatures, additional coatings or protective layers are essential.

Guangqi’s coated pipes and steel-plastic composite pipes are specifically designed for harsh environments. The inner and outer coatings provide extra protection against moisture, acid, and alkaline exposure, ensuring a longer lifespan and lower maintenance costs.

Assessing Load and Pressure Requirements

Engineering projects often involve varying levels of mechanical stress and internal pressure. It is crucial to choose pipes that can handle the expected loads without deformation or rupture. For example, water distribution systems, gas pipelines, and fire protection networks all require different pressure ratings.

Guangqi manufactures galvanized pipes and ductile iron pipes with robust mechanical properties suitable for both low- and high-pressure systems. Ductile iron pipes, in particular, offer exceptional tensile strength and flexibility, making them ideal for underground and municipal applications.

Considering Design and Structural Applications

When pipes are used for structural or architectural purposes, such as in building frameworks, railings, or scaffolding, aesthetics and shape also play a role. Round pipes are generally used for fluid transport, while galvanized square and rectangular tubes provide stability and clean lines for structural and decorative installations.

Guangqi’s square and rectangular tubing is engineered to meet the requirements of modern construction projects, combining high strength with a sleek appearance. Their uniform zinc coating enhances resistance to environmental wear and mechanical stress.

Balancing Cost, Quality, and Longevity

Budget considerations are always important in project planning. While some materials may appear cheaper upfront, they can lead to higher maintenance or replacement costs in the long run. Galvanized pipes strike an excellent balance between affordability and durability.

By choosing Guangqi’s products, project owners gain access to a full spectrum of cost-effective and high-performance piping solutions. Each product line undergoes rigorous quality control to ensure compliance with international standards, helping customers achieve both economic and technical efficiency.

Ensuring Compliance and Standards

Before finalizing your pipe selection, always verify that the materials meet the required engineering and safety standards. Guangqi’s galvanized pipes and related products comply with ISO, ASTM, and EN specifications, ensuring compatibility and reliability for global projects.

With professional technical support and custom manufacturing options, Guangqi can provide pipes tailored to specific dimensions, coatings, and performance requirements, offering engineers complete confidence in their material choices.

Conclusion

Selecting the right galvanized steel pipe is more than a technical decision—it’s an investment in the durability and success of your engineering project. By considering environmental conditions, mechanical requirements, design needs, and budget, engineers can make informed choices that enhance project performance and longevity.

With its wide range of galvanized steel pipes, steel-plastic composite pipes, coated pipes, galvanized square and rectangular tubes, and ductile iron pipes, Guangqi stands as a reliable partner in delivering high-quality, efficient, and sustainable piping solutions for every application. Whether for infrastructure, construction, or industrial systems, Guangqi’s commitment to innovation and quality ensures that every project is built to last.

From Corrosion Resistance to Durability: Understanding Galvanized Steel in Engineering Pipelines

http://www.gqsteelpipe.com

Foshan Nanhai Guangqi Steel Industry Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.